#3 Digging Through Designs: The Transmission Team Starts from Scratch (Part 1)

This series features Toyota’s project to revive a legendary racing car by reporting on the project members’ efforts as well as the history and meaning behind this vehicle. The third part focuses on the team rebuilding the transmission.

Three men with three different roles

Hideaki Asuka, Tatsuki Honda, and Hidenao Ishida form the team in charge of the car’s transmission, clutch, driveshaft, and rear axle.

Asuka, with 12 years of experience at Toyota, normally designs and produces molds for resin components, such as the carbon-fiber-reinforced polymers (CFRP) used in GR and Lexus vehicles as well as racing cars. He is a motorsport enthusiast who competes in an endurance race once a year with a Toyota 86 tuned for racing by a company team.

Asuka

I put my hand up for the revival project. I saw it as a great opportunity to understand every aspect of car production. Such chances don’t come along in my regular work.

Honda, in his seventh year at Toyota, currently designs drive units for hybrid electric vehicles.

Honda

My regular assignment is probably the most closely related to this project of the three of us. Even so, the transmission of a very old manual car is completely different from that of a motor-driven hybrid system. I’ve often had to figure things out from scratch, which is a great learning experience.

Honda says his division manager offered the opportunity to work on the revival project. Like Asuka, he had a desire to see the whole car production process.

Ishida, in his 12th year, is in the prototype development division and responsible for prototype quality control, particularly of electrical components. He was previously in a design division, so he was assigned to design duties in this project.

Ishida had an interesting conversation with his manager when deciding to take part in this project.

Ishida

When my manager asked if I was available for more work, I first replied, “No.” Then he told me about this project and asked if I wanted to try it because other division members had turned down the offer. After I saw what an interesting project it was, I wanted to take the chance, so I said, “Actually, I’m not that busy. I’d love to do it.” I find it amazing that our predecessors took on the challenge of building such a race car just five or six years after World War II.

None of the three had ever heard of the Toyopet Racer before. “After I decided to take part, I did some reading on the race car and was really impressed. I had no idea such a car had existed,” recalls Asuka.

A two-month struggle with the original blueprints

The project has a major guiding principle: the work is to be done by hand without relying too much on today’s technology, channeling the spirit of the car’s original makers.

And yet, time and budget are limited. The project members discussed and decided to divide revival work into parts that could be made quickly and cleverly at low cost and those that would be crafted with attention to detail.

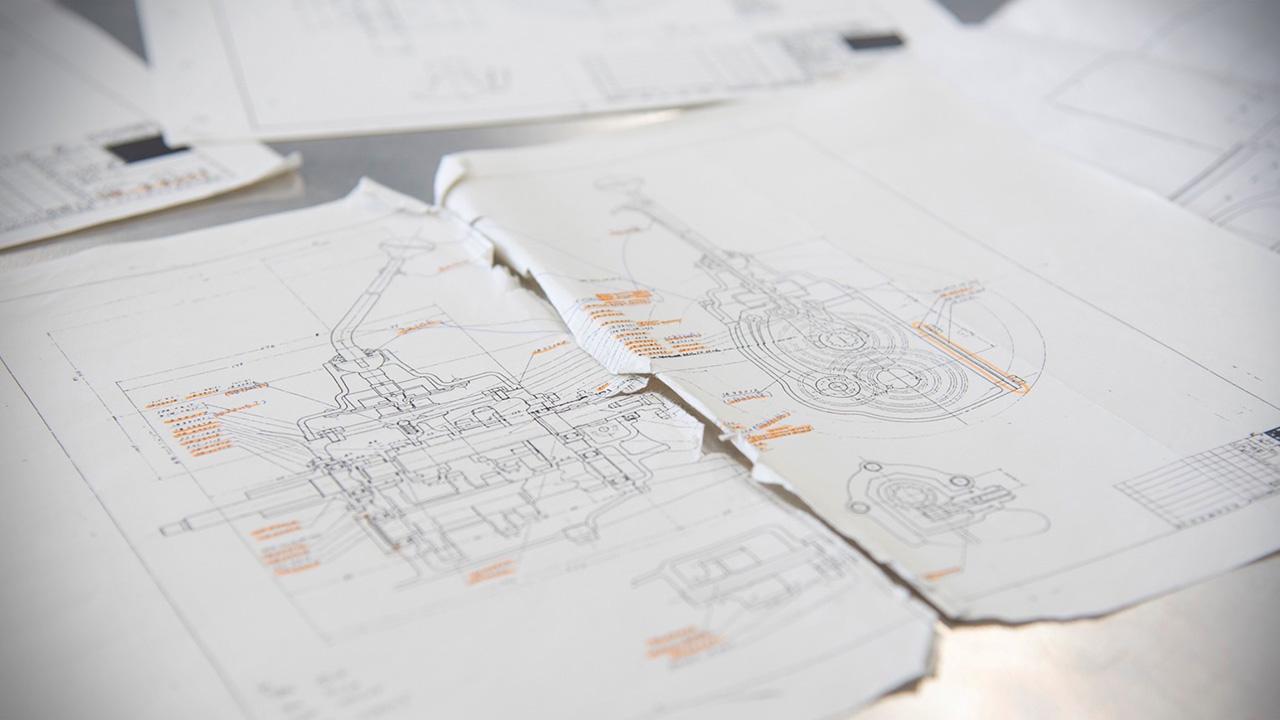

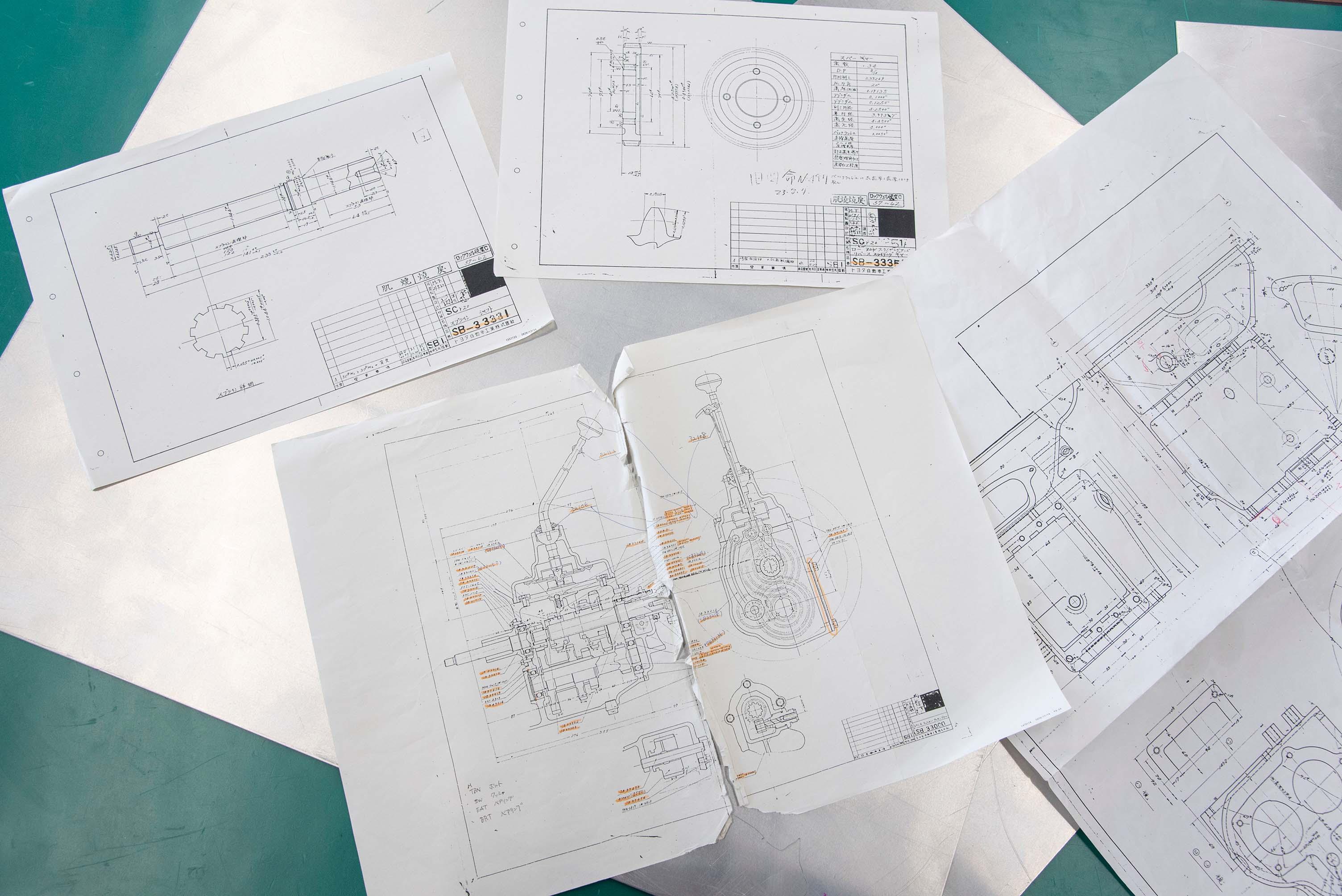

The three-person transmission team chose to focus efforts on reconstructing the manual transmission according to 70-year-old design drawings. Generic components were used for parts such as the driveshaft and the differential.

For the engine itself, the initial plan was to restore and use an S-type engine that had been stored in the Toyota Automobile Museum, but it lacked a transmission. At this point, the only option was to build from scratch.

The trio’s first step was to gather and pierce together design drawings for the Toyopet Model SD, a base model of the Toyopet Racer.

Asuka

After seeing sectional drawings of the Toyopet Model SD transmission assembly, the first thing we did was check that blueprints for the depicted parts were still available. Fortunately, the drawings were all there. We thought we could easily make the parts.

However, as they delved deeper, the team ran into problems that the drawings alone could not solve, which they would have to figure out for themselves.

Honda

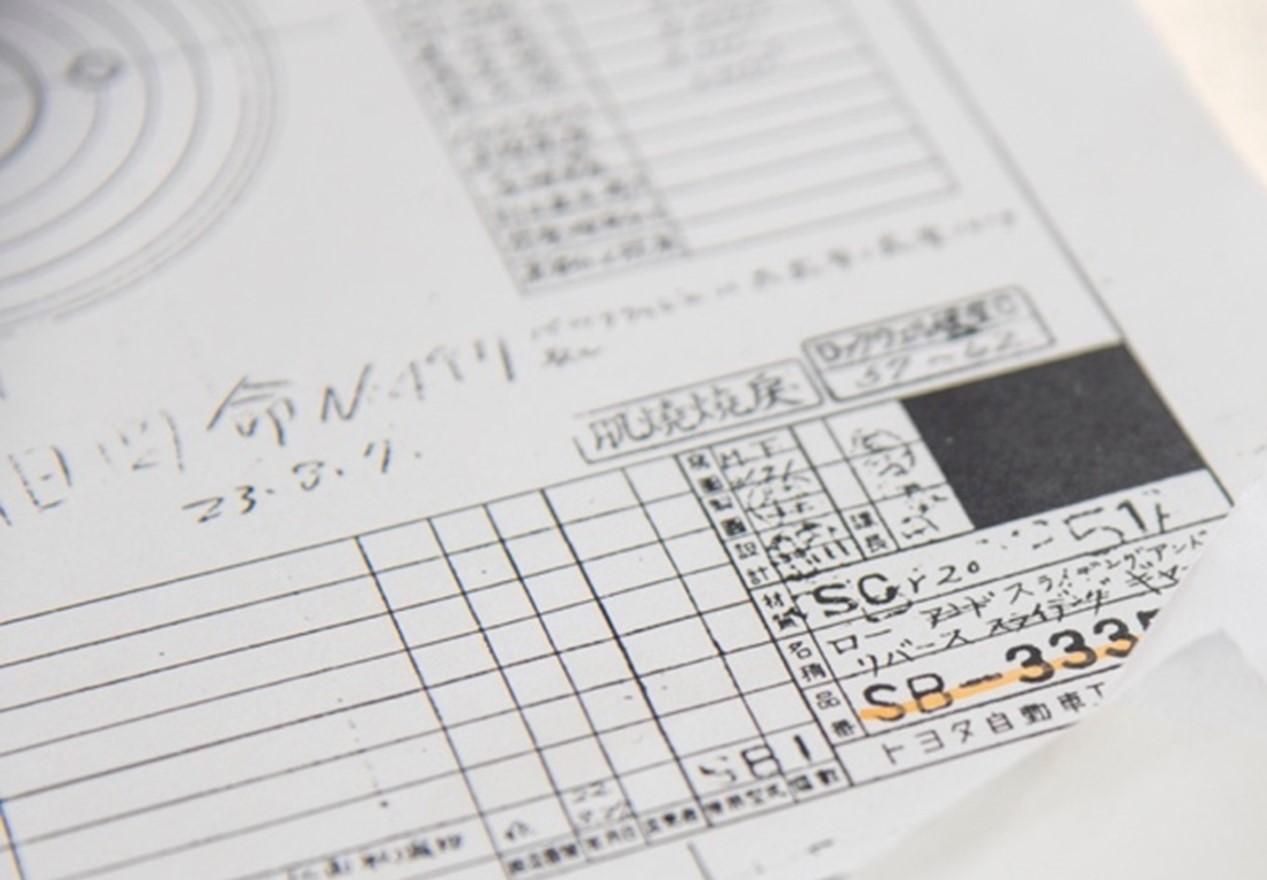

The old parts blueprints were numbered, followed by letters—A, B, C, D and so on. These indicate design changes made after the original drawings. The problem was that only one or two of each had been saved. Design changes were frequently made in the drawings, so we had no way of knowing whether the remaining blueprints were the ones actually used to make the Toyopet Racer. We had to verify each one, ensuring the parts were compatible with each other, to figure out which versions of the drawings to use for rebuilding.

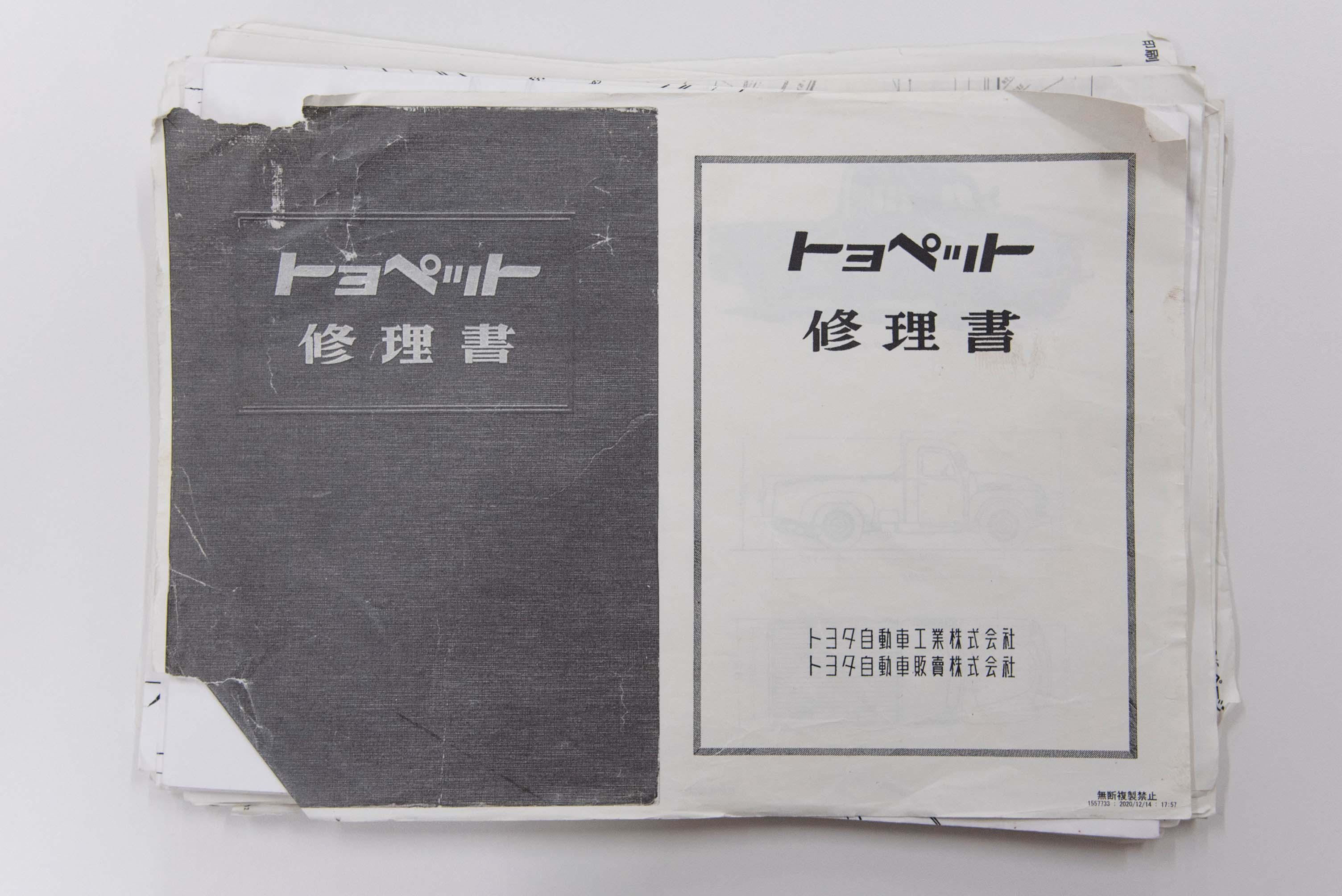

Original repair manuals which described the parts and how they were put together for those servicing the car also proved extremely helpful in verifying component structure.

Museum exhibits provide another valuable reference

The team still lacked some pieces of the puzzle even after scrutinizing the original design drawings and repair manuals. They needed to get a clear idea of components that weren’t described in the documents.

The team examined the parts details on a real Toyopet Truck Model SG to find what was missing, because the truck uses essentially the same transmission as the Toyopet Model SD passenger car.

They borrowed the vehicle from the Toyota Automobile Museum and placed it in a corner of the project’s main room. It served as a textbook for each team.

Ishida

We crawled under the car to examine the geometry of parts and how they fit together. It was an invaluable reference when making components.

Honda

Seeing this car for ourselves finally gave us a clear idea of the parts we couldn’t work out from drawings alone, allowing us to push forward with the rebuilding work. I’m very grateful that we were able to borrow the car.

The amazing skill of creating compatible parts from drawings

The team also found joy in the historical research despite the unglamorous, arduous nature of the rebuilding task. The trio realized that, back in the day, their predecessors had been studying foreign technologies, with design and manufacturing working as one to build the car.

Asuka

Some important information about these components, such as the height of transmission gear teeth, is written in inches while the surviving blueprints mostly use the metric system. That’s probably because the key technical parts were modeled on foreign technology.

Honda

On top of that, some drawings don’t provide tolerances, only noting the target values for dimensions. There are also many places where the dimensions appear to have been revised repeatedly. They likely arrived at these dimensions after repeated trial and error of making and testing parts. I saw the inherited practice of visiting the genba (work site) to check drawings against actual conditions.

Ishida

I think that they were able to build a car through continuous trials thanks to the highly skilled people on the production floor. They were able to shape and hone each part by hand and gauge how these real components fit together. I’m sure there were many people with incredible skills working on the project.

The trio was finally ready to begin producing new parts after two months of steady checking and verifying. Part two of this article showcases the transmission team’s monozukuri (manufacturing) efforts.

(Text: Yasuhito Shibuya)